Total precision.

Highest quality

We manufacture all plastic parts as specified by you – customized, precise, and fast – or jointly develop product solutions tailored to your needs.

High-quality solutions for industry, construction and trade

First-class thermoplastic injection molding product know-how is our hallmark.

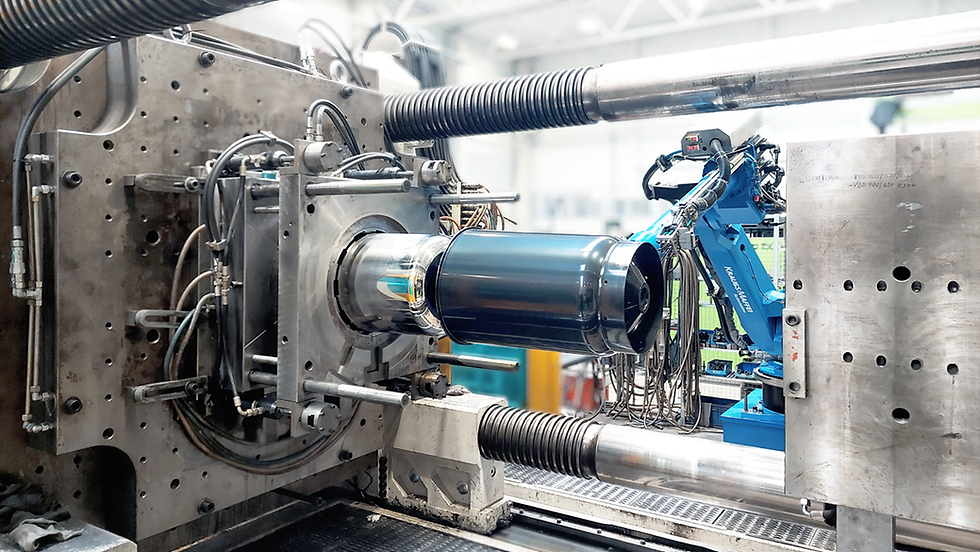

We produce all of our customers' components with the highest quality, from several hundred thousand small parts to large and heavy individual pieces. To this end, we continuously develop our manufacturing processes, test new production methods, or develop new compounds and optimize processes to give our customers a competitive edge.

After all, we know our customers and their industries, and our work ensures that they will be able to meet the demands of the market now and in the future.

Our expertise for your success

As early as during the development of components, we support you with our expertise and provide holistic advice on design, materials, and cost-effective production. That's how we combine modern process technology with high-quality standards for results that are never anything less than compelling.

We injection mold up to 13 kg of unit weight from almost all thermoplastics. Our expertise is based on highly qualified, competent staff, state-of-the-art production equipment, and, last but not least, our many years of experience in the manufacture of technical plastic injection molded parts. Our in-house toolmaking shop also enables us to offer all manufacturing steps from a single source, which makes us highly flexible.

-

Neue Fertigungsmethoden, die Effizienz und Präzision steigern.

-

Innovative Materialentwicklungen, um Ihre Produkte langlebiger und leistungsstärker zu machen.

-

Optimierte Verfahrenstechniken, die Ihnen einen Vorsprung in einem dynamischen Marktumfeld verschaffen.

Mit unserem tiefen Branchenverständnis und unserer kundenorientierten Arbeitsweise sorgen wir dafür, dass Ihre Produkte auch morgen den höchsten Anforderungen gerecht werden.

Technical injection molded plastic parts: unlimited possibilities

Here are some examples from a variety of possible applications.

Wissenswertes über Technik und Material

Home automation components

Preterm medicine and incubators

Components for lighting systems in industrial plants

Covers for the hospitality industry

Waste baskets and kitchen waste containers

Drainage gutters

Trash cans and large trash containers

Components for lighting systems for industrial and production facilities as well as commercial buildings

Components for parking meters or access control

Transport and varioboxes, transport systems for retail and wholesale trade

Our expertise for your success

As early as during the development of components, we support you with our expertise and provide holistic advice on design, materials, and cost-effective production. That's how we combine modern process technology with high-quality standards for results that are never anything less than compelling.

We injection mold up to 13 kg of unit weight from almost all thermoplastics. Our expertise is based on highly qualified, competent staff, state-of-the-art production equipment, and, last but not least, our many years of experience in the manufacture of technical plastic injection molded parts. Our in-house toolmaking shop also enables us to offer all manufacturing steps from a single source, which makes us highly flexible.

Unsere Expertise umfasst dabei auch die Verarbeitung von glasklaren und recycelten Kunststoffen, wodurch wir innovative Lösungen für Branchen wie

-

Medizintechnik,

-

Hotellerie,

-

Freizeit und Lifestyle

anbieten können.

Our expertise for your success

As early as during the development of components, we support you with our expertise and provide holistic advice on design, materials, and cost-effective production. That's how we combine modern process technology with high-quality standards for results that are never anything less than compelling.

We injection mold up to 13 kg of unit weight from almost all thermoplastics. Our expertise is based on highly qualified, competent staff, state-of-the-art production equipment, and, last but not least, our many years of experience in the manufacture of technical plastic injection molded parts. Our in-house toolmaking shop also enables us to offer all manufacturing steps from a single source, which makes us highly flexible.

-

Konstruktionsberatung für funktionale und kostenoptimierte Designs.

-

Materialauswahl basierend auf den spezifischen Anforderungen Ihres Projekts.

-

Wirtschaftliche Produktion, die Qualität und Budget in Einklang bringt.

Our expertise for your success

As early as during the development of components, we support you with our expertise and provide holistic advice on design, materials, and cost-effective production. That's how we combine modern process technology with high-quality standards for results that are never anything less than compelling.

We injection mold up to 13 kg of unit weight from almost all thermoplastics. Our expertise is based on highly qualified, competent staff, state-of-the-art production equipment, and, last but not least, our many years of experience in the manufacture of technical plastic injection molded parts. Our in-house toolmaking shop also enables us to offer all manufacturing steps from a single source, which makes us highly flexible.

-

Hochqualifizierte Fachkräfte, die jeden Prozess begleiten und optimieren.

-

Modernste Fertigungsanlagen, die Präzision und Effizienz garantieren.

-

Eigener Werkzeugbau, der eine nahtlose Integration aller Fertigungsschritte ermöglicht und maximale Flexibilität bietet.

Our expertise for your success

As early as during the development of components, we support you with our expertise and provide holistic advice on design, materials, and cost-effective production. That's how we combine modern process technology with high-quality standards for results that are never anything less than compelling.

We injection mold up to 13 kg of unit weight from almost all thermoplastics. Our expertise is based on highly qualified, competent staff, state-of-the-art production equipment, and, last but not least, our many years of experience in the manufacture of technical plastic injection molded parts. Our in-house toolmaking shop also enables us to offer all manufacturing steps from a single source, which makes us highly flexible.

In-house materials development. Innovation for our customers.

With our in-house development work on material optimization, we make a significant contribution to our customers' economic success.

Our goal is to develop customized compounds to optimally align the properties profile of the plastic with its application.

Do you have any questions?

If you have any questions about plastic molded parts, just give us a call or send us an e-mail - we'll be happy to help.

Phone +49 291 95295–292

In 2021, we processed a total of 4,800 tons of material, 2,000 tons of whichwas secondary material. That corresponds to a volume of nearly 20 truckloads of plastic per month.

Anwendungen für Spulen